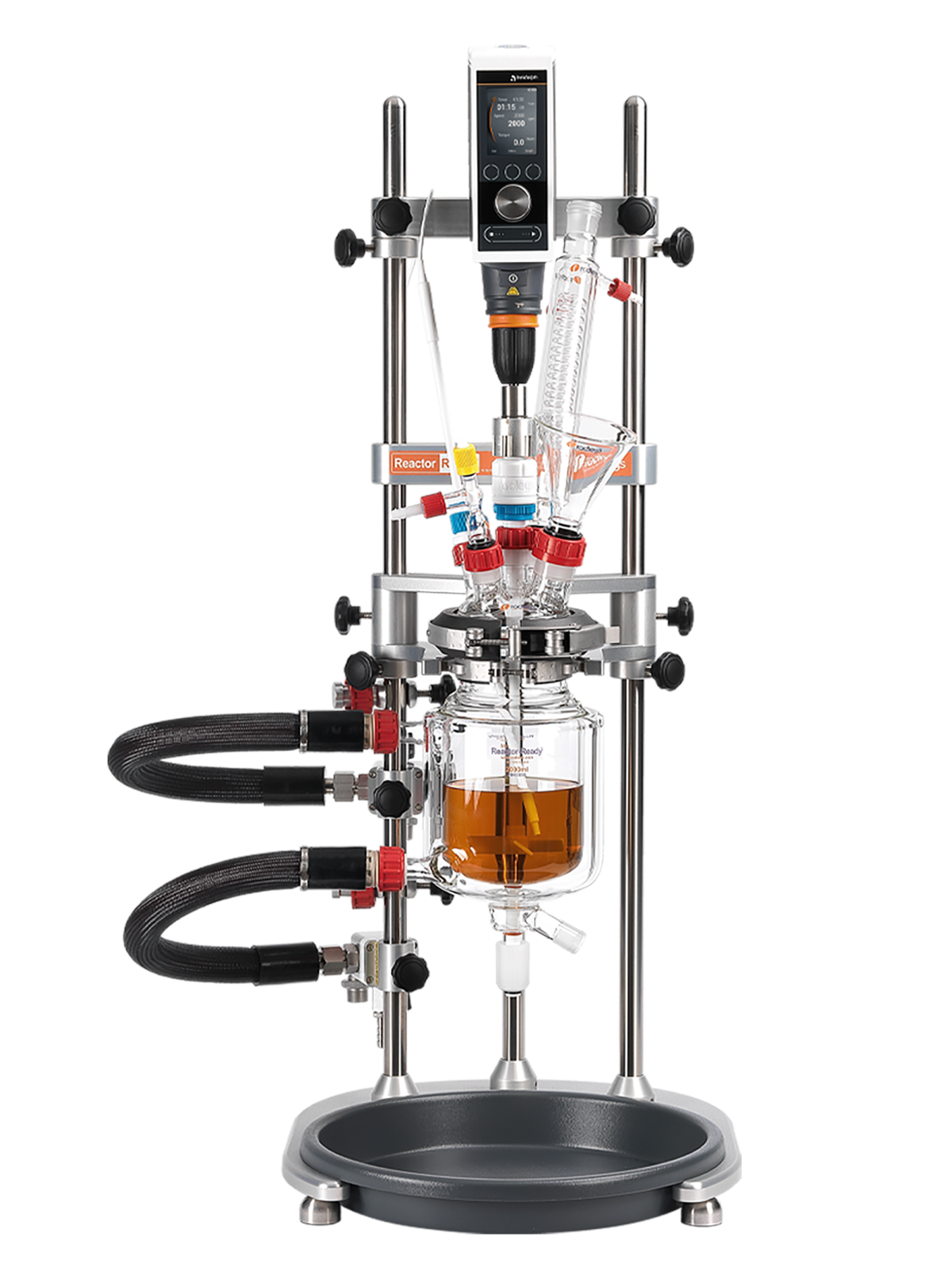

Reactor-Ready Flex Lab Reactor

The Reactor-Ready Flex Lab Reactor from Radleys is the versatile all-in-one solution for chemical syntheses, process development and scale-up studies.

It was specially developed for laboratories that work with changing volumes (100 ml to 5 liters) and different configurations. And all this without having to purchase new equipment!

Vessels can be changed in just a few minutes and without tools – supported by PEEK quick-release couplings, self-aligning stirrer couplings and practical quick-release clamps.

The stable frame, the wide temperature range from -70 °C to +230 °C and the compatibility with various temperature control units make the Reactor-Ready Flex the ideal system for a wide range of applications.

There are two pre-configurations to choose from, depending on budget and requirements:

Starter and Pro.

-

Figures 3 and 4 show the starter system,

-

Figures 1 and 2 show the Pro system,

-

Figure 5 the Pro system with integrated distillation apparatus.

In combination with the optional AVA software, the temperature, stirring speed and pH value can be monitored and controlled automatically. This enables reproducible processes and provides valuable data for process optimization.

Reactor-Ready Flex Lab Reactor stands for maximum flexibility, efficiency and safety in the laboratory.

Click here for the demo video.

Reactor-Ready Flex: Modular double-walled reactor system for the laboratory | Radley's Reactor-Ready Pro vs Starter Demo

Discover Reactor Ready Flex, a modular double-walled reactor system from Radleys, designed for maximum adaptability, safety and efficiency in chemical synthesis and process development.

Reactor Ready Flex is designed for laboratories that need flexibility with different reaction vessels and process conditions and offers a configurable solution tailored to your application and budget.

Two vessels on one frame?

Reactor-Ready Duo has the same unique features as Reactor-Ready, but has two independent reaction vessels made of jacketed glass. The system can be configured to operate with a single thermostat that simultaneously controls the jacket temperature of both vessels or with two thermostats that independently control the temperature of each vessel.

Drying and inerting the reaction

Drying and inerting the reaction is an important process in upscaling. In this video, Steve Bendefy explains how this is best done on the Radleys reactors.

IGZ Instruments AG - Your inquiry forReactor-Ready Flex Lab Reactor